Concetti has started work on the expansion and digital transformation of its headquarter in Bastia Umbra, Italy. The company design, manufactures and exports fully automatic machines and systems for packaging bulk products. Each project is tailored to the customer’s specific needs.

The 5 – million Euro investment is to satisfy increased demand for its automated packaging systems manufactured in Bastia Umbra and exported to more than 60 countries across the world. The expansion plan, aimed at both modernizing its headquarters and increasing the company’s manufacturing capacity, will improve its product and service provision to customers. In order to prepare for the installation of many more new systems in the coming years, the expansion will add an extra 58,000 square feet (5400 square meter) to the existing Concetti headquarters site.

The investment also concerns the digitization of production. Concetti will be a “smart factory” with integrated IT systems to simplify the manufacturing processes and increase efficiency. Greater emphasis on worker safety, improving energy consumption from renewable energy sources and better environment sustainability are also key to the project.

The company expects the expansion to be completed over the course of 2018. At present the site in Bastia Umbra employs close to 220 people. Concetti celebrate its 100th anniversary in 2018. The company was founded in 1918 for manufacturing agricultural equipment. The packaging equipment group was established in 1976.

*******

Si chiuderanno nel giugno 2018 i lavori di ampliamento e ammodernamento del sito produttivo della Concetti di Bastia Umbra (Pg). Lo stabilimento della società passerà da una superficie di 8600 a 14000 metri quadrati, e sarà provvisto di tutte le più moderne tecnologie in chiave Industria 4.0. La fabbrica sarà dotata di infrastrutture automatizzate e sistemi digitalizzati e interconnessi, e saranno implementati tutti gli aspetti legati alla sostenibilità ambientale, alla sicurezza e salute dei lavoratori. L’investimento è di circa 5 milioni di euro.

Concetti have joined the PPMA, Processing and Packaging Machinery Association. The British group of associations comprising more than 500 member companies, has been active since 1987 and is a benchmark for processing and packaging professionals promoting the benefits of machine innovations enabling the market access to the latest technical information and advice.

Concetti have joined the PPMA, Processing and Packaging Machinery Association. The British group of associations comprising more than 500 member companies, has been active since 1987 and is a benchmark for processing and packaging professionals promoting the benefits of machine innovations enabling the market access to the latest technical information and advice.

Concetti headquartered in Bastia Umbra, Italy, designs and manufactures fully automatic machines and systems for packaging bulk products, and has over 50 plants installed all over the United Kingdom. Concetti has been present in England since the early 1980s with a qualified technical assistance partner. Our PPMA membership is to provide the best quality to our customer.

Concetti will exhibit at the PPMA show taking place in Birmingham, UK, from 25 to 27 September, 2018 and look forward to discussing our solutions with all existing and new customers.

For more info:

****

Concetti è entrata a far parte della PMMA, l’associazione delle aziende per il processo e il confezionamento inglese. L’associazione di categoria è attiva dal 1987 include più di 500 membri di diversi settori ed è un punto di riferimento per le aziende del settore del packaging.

L'azienda italiana che progetta e costruisce macchine per l’insacco e la pallettizzazione, ha oltre 50 impianti installati in tutta la Gran Bretagna ed è presente in Inghilterra dall'inizio degli anni 80, con un partner qualificato per l’assistenza tecnica. L'appartenzenza a PPMA servirà a garantire ancora maggiore qualità ai nostri clienti.

Concetti sarà presente alla fiera PPMA di Birmingham, Gran Bretagna, dal 25 al 27 settembre 2018 e sarà lieta di incontrarvi.

Volteco Italia, a specialist manufacturer of above and below ground waterproofing solutions for the construction industry have installed a complete Concetti bag filling and palletising line at their Ponzano Veneto plant near Treviso, Italy. Volteco’s product range covers a system of rigid panels but also includes many highly specialised, cement based waterproofing premixes including coatings, renderings and repair concretes. However, even waterproofing premixes must be kept dry before use.

So, the new line takes advantage of the latest developments in PE film technology coupled with Concetti’s advanced tubular Form, Fill Seal systems to package these cementitious premixes in water resistant, clean, secure bags that can release excess air but still safely be stored outside without detriment to the product. The secret is in the particular design of micro perforations built into the inner ply of an overlapped seam produced during the tubular film’s manufacture. Air is allowed to escape slowly through the overlapped seam and out via small vents automatically created during the forming and sealing operations.

So, the new line takes advantage of the latest developments in PE film technology coupled with Concetti’s advanced tubular Form, Fill Seal systems to package these cementitious premixes in water resistant, clean, secure bags that can release excess air but still safely be stored outside without detriment to the product. The secret is in the particular design of micro perforations built into the inner ply of an overlapped seam produced during the tubular film’s manufacture. Air is allowed to escape slowly through the overlapped seam and out via small vents automatically created during the forming and sealing operations.

The new line replaces a conventional vertical FFS machine using single wound film with ordinary micro perforations. Volteco clearly recognised the traditional benefits of PE film, the lower cost, better branding opportunities and easier recycling of the empty bags compared to multi-wall paper but unfortunately these benefits were being offset by some serious disadvantages on the existing system.

Vertical FFS machines are often problematic when operating on fine powders because contamination of the seal area causes frequent seal failures and subsequent spillage both at the manufacturing stage and throughout the product’s life. The simple micro perforation system allows dust and air to escape and moisture to enter, even with correctly sealed bags. Dry, covered storage is essential if consequent product degradation and loss is to be avoided.

The new Concetti line overcomes these drawbacks. The Continua tubular FFS system combined with innovations in film technology keeps all of the traditional benefits of PE film, but adds cleaner packs, more secure sealing and vastly superior protection against moisture ingress, a crucial factor for any cement based material and one designed to appeal to manufacturer, wholesaler, retailer and user alike. Being able to store outside saves warehousing costs and cuts waste from product degradation right up to the moment of use. Volteco will be the first Italian company to install this type of Concetti technology on cement premixes.

Concetti, based near Perugia in Italy, has a long experience in manufacturing complete filling lines including tubular form, fill and seal machines. The growing demand for machines that can take real advantage of the latest PE films, particularly for cement based products, has led to further development of the well known Continua range. The Ponzano Veneto plant will use the extended six-station variant that allows extra deaeration systems to be added specifically to handle fine powders and powder based products.

The dosing and filling system (photo courtesy of Volteco) is flexible enough to handle the required range of products with pack weights of 15-25Kg, film widths between 290-400mm and bag lengths between 460-840mm without change parts or spanner adjustments. Output depends on the product handled but is between 360 and 500 bags/hr. Product dosing is by screw feeder with hardened wear surfaces feeding a net weigher. To avoid contamination when changing products, interlocked inspection doors are fitted together with a novel cleaning system for the screw. This is reversible to discharge any residue left at the end of a production run via a rear flap and chute into a waiting container at ground level. Air jets then clean the internal screw surfaces. This minimises downtime between changeovers and is a key part of the Concetti philosophy to provide flexible packaging systems able to switch rapidly from one product to another without contamination and with as little manual intervention as possible.

The Continua has six stations through which the bag passes and each for a specific task. Firstly to form a bag of the correct length from the reel of tubular film and seal the bottom. A second station fills the bag with a pre-weighed quantity of product and applies the first stage of deaeration. The filled bag is moved to a third station where bottom vibration settles the product. A fourth station applies further deaeration and the fifth station cleans the seal area with a blast of air before closing the pack by powerful heat-sealing jaws. The last station cools the seal to ensure its integrity before the bag is released to undergo a final check that the seal is good with no leakage detected.

During the sealing operation it is also possible to apply a partial vacuum to remove any remaining excess air between the top of the product and the seal and so provide a firm, compact, well-shaped bag that can safely be palletised. Changes in bag length are made automatically under programme control using servomotors on the machine.

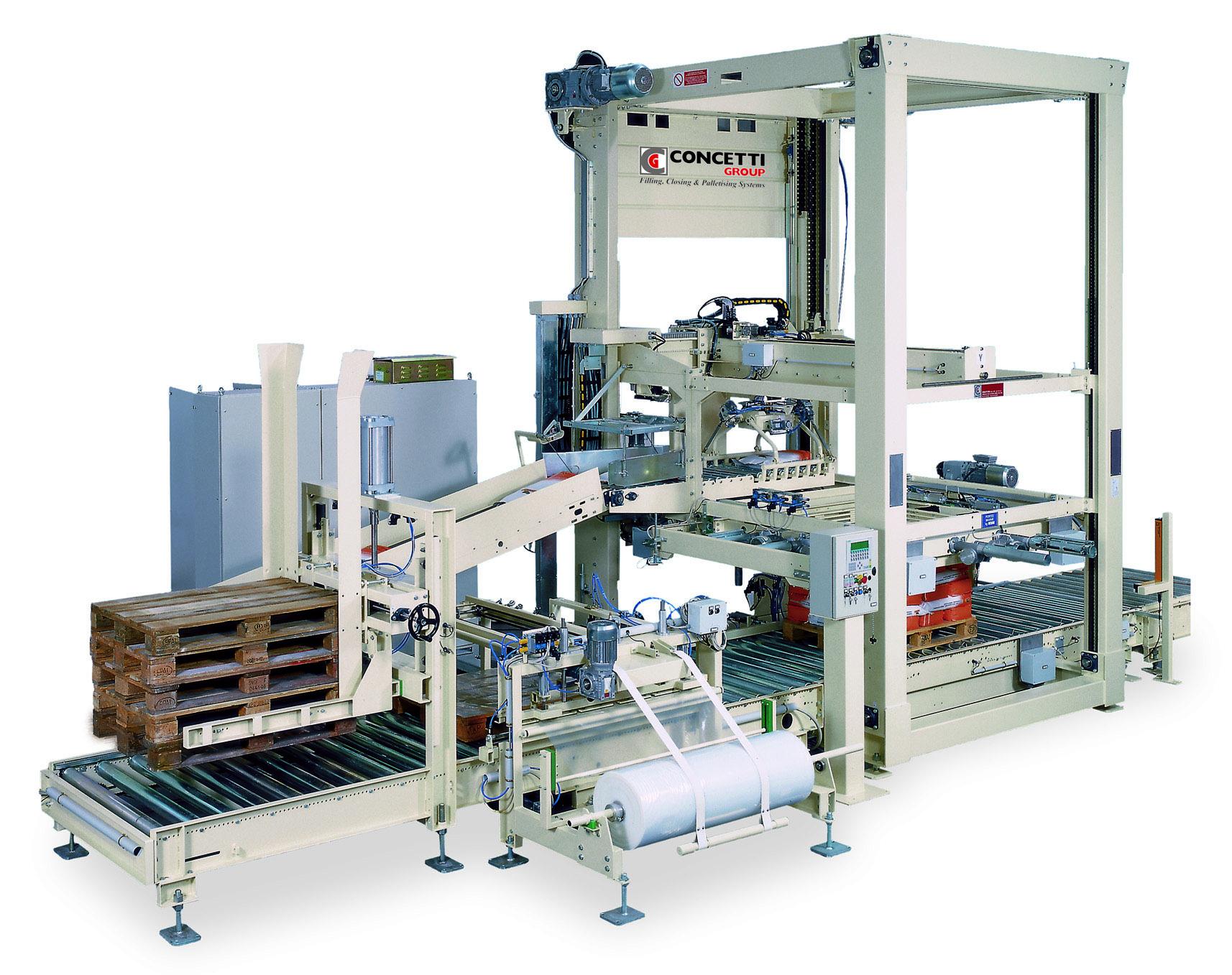

From the Continua, belt conveyors transfer bags through a short pressing operation to a Concetti "PS-3A four column" robot palletiser equipped with empty pallet dispenser, PE film bottom sheet dispenser and automatic pallet squaring. Bags are centred on entry to the palletiser by guides, which are adjusted automatically for different bag widths whenever the programme changes. Unlike single column machines, the PS-3A palletiser has motorised layer conforming plates operating under programme control and positioned according to the layer size. A stripper plate avoids any loss of output during pallet exchange cycles and provides top compression of individual layers. The result is a highly flexible machine that delivers neat, square pallets every time. A stretch hooder supplied by the customer completes the line.

From the Continua, belt conveyors transfer bags through a short pressing operation to a Concetti "PS-3A four column" robot palletiser equipped with empty pallet dispenser, PE film bottom sheet dispenser and automatic pallet squaring. Bags are centred on entry to the palletiser by guides, which are adjusted automatically for different bag widths whenever the programme changes. Unlike single column machines, the PS-3A palletiser has motorised layer conforming plates operating under programme control and positioned according to the layer size. A stripper plate avoids any loss of output during pallet exchange cycles and provides top compression of individual layers. The result is a highly flexible machine that delivers neat, square pallets every time. A stretch hooder supplied by the customer completes the line.

The entire system is intended to be easy to clean and operate. Concetti’s use of servomotors to replace manual adjustments allows changes to product and bag size to be made simply by changing programme. Each product has a unique programme number and each programme is a list of the variable parameters that need to be changed to accommodate different bag sizes and weights. A network links the PLCs and the weight controller and allows settings for the entire line to be changed from one operator terminal simply by selecting a new programme number.

Not only does this flexibility mean the line is quickly set up for new products, it also avoids operator set-up errors. Crucial decisions that affect the line’s operation are outwith the operator’s control. Concetti say that after clean down, this changeover can be completed, ready to run in under 90 seconds and represents the perfect use of digital technology to simplify complexity and make the line as easy to manage as possible as well as reliable and efficient. Only the film then needs to be changed before the line is restarted and usually, just one operator per shift is enough.

Concetti have the added advantage of manufacturing every element of the dosing, filling and palletising system in their own factory where the integration is made and the complete system is tested under simulated site conditions using the customer’s own materials, PE film reels and pallets before shipment. This ensures the end user is satisfied with the performance before receiving the equipment and that when reassembled on site, commissioning and start-up is quick and trouble free.

The superiority of tubular FFS systems is shown once again. Coupled with the latest PE films and Concetti’s wide experience in these cement based applications, the result is a low cost, secure, clean, colourful and well presented pack able to withstand outside storage in all weathers without diminishing either the quality or performance when it comes to be used. These new FFS systems will appeal to cementitious premix producers who are increasingly bringing new products to world markets for specialised uses in building and construction.

Article edited by Worldcement, 2017

Concetti S.P.A, Bastia Umbra, Italy, has supplied two full line bagging lines for animal feed to Mignini&Petrini, an established famous name in the Italian food industry.

Concetti S.P.A, Bastia Umbra, Italy, has supplied two full line bagging lines for animal feed to Mignini&Petrini, an established famous name in the Italian food industry.

The main requirement for Mignini&Petrini in the modernisation of its packaging plants is to be increasingly competitive in the stockfeed market, not only providing retailers with improved packaging but also giving the end user higher quality products whilst paying special attention to the environment with a reduced use of plastics.

Concetti S.p.A has supplied the most innovative, efficient and cutting edge technologies available. Two fully automatic turnkey lines each consisting of

This type of high speed line, characterised with the ultimate flexibility, is the Concetti flagship feature, enabling customers to easily package – with just one plant – different kinds of animal feeds ranging from powders to cubes, as well as ground, flat, flaky and laminated products.

The capacity of the bagging machine is up to 1,200 bag/h when handling free flowing products in 25 kg bags. Stoppage time between products is reduced to a minimum by the Concetti fully automatic changeover feature taking just 60 seconds from the HMI keyboard.

The neat, square shape of the finished pallets are a result of the layer squaring and compression feature of the Concetti four-column palletiser that guarantees this packaging system remains one step ahead.

Info: salesitaly.com

Mignini&Petrini, storico marchio dell’industria mangimistica italiana, raddoppia. L’azienda si doterà di due nuove linee veloci completamente automatiche per il confezionamento dei mangimi per animali da reddito, progettate e fornite da Concetti S.P.A di Bastia Umbra. L’esigenza della Mignini&Petrini era quella di modernizzare gli impianti di confezionamento per essere sempre più competitiva sul mercato dell’alimentazione animale, garantendo ai propri rivenditori una confezione sempre migliore e al cliente finale un prodotto di qualità superiore, con un’attenzione speciale alla sostenibilità ambientale grazie all’impegno nella riduzione dell’utilizzo della plastica.

Concetti S.P.A, azienda produttrice da oltre 40 anni di impianti di pesatura, insacco e pallettizzazione per mangimi e petfood, tutti conformi al pacchetto di incentivi “Industria 4.0”, ha messo a disposizione dell’industria umbra, le tecnologie più innovative ed efficienti disponibili nel settore della mangimistica. Si tratta di due sistemi “chiavi in mano” completamente automatici di quasi trenta metri di sviluppo ciascuno, composti da doppia bilancia a peso netto ad alta precisione con sistema di alimentazione a nastro, insaccatrice per sacchi a bocca aperta della serie “IGF 1200”, palettizzatore robotizzato “a quattro colonne” e un innovativo fine linea per avvolgere le palette in maniera più sostenibile.

Questa tipologia di linea veloce è caratterizzata da una grande flessibilità, marchio di fabbrica di Concetti, che permette al cliente di gestire agilmente, con un solo impianto, tutti i diversi tipi di mangime per animali da reddito, dalle farine ai cubettati, passando per sbriciolati, schiacchiati, fioccati e laminati. I tempi di fermo macchina sono ridotti al minimo, grazie al cambio di formato completamente automatico che avviene in appena 60 secondi dal pannello di controllo.

La capacità produttiva dell’insaccatrice raggiunge i 1200 sacchi all’ora con i prodotti più scorrevoli in confezioni da 25 kg. Punto di forza dell’impianto è, infine, il pallettizzatore a quattro colonne, testa di serie della gamma robotizzata Concetti, dotato di una pinza che si muove lungo tre assi cartesiani e nel contempo ruota attorno al proprio asse verticale. Una macchina affascinante e robusta dall’elevata flessibilità che permette di manipolare sacchi con prodotti diversi e differenti livelli di riempimento, con la possibilità di ottenere anche la parziale sovrapposizione dei sacchi, conferendo grande stabilità al carico.

For many users, FIBCs (Flexible Intermediate Bulk Containers) represent a convenient method of handling and transporting a huge variety of different products from cereals to cement and plastic pellets to chemical powders. Every year millions of tonnes of products are transported in these highly cost effective containers with a capacity, usually between 500kg and 2000kg. Concetti in Perugia, Italy has a wide range of products for filling these FIBCs from simple gross weighing systems for applications around 20 big bags per hour.

For many users, FIBCs (Flexible Intermediate Bulk Containers) represent a convenient method of handling and transporting a huge variety of different products from cereals to cement and plastic pellets to chemical powders. Every year millions of tonnes of products are transported in these highly cost effective containers with a capacity, usually between 500kg and 2000kg. Concetti in Perugia, Italy has a wide range of products for filling these FIBCs from simple gross weighing systems for applications around 20 big bags per hour.

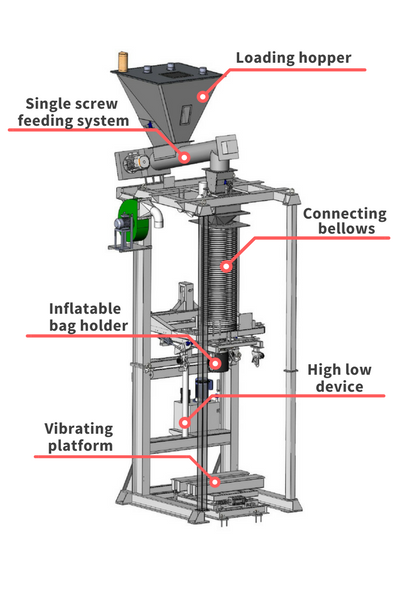

From the feeding devices developed over many years to cope with different products to the expertise in dynamic weighing and pallet handling, Concetti has both the experience and resources to provide FIBC filling systems that are reliable as well as easy and safe to use. The entry-level machine is the simplex gross weigher where bag and product are weighed together. Depending on the product characteristics, be it granular free flowing, a fine powder or coarse and lumpy, the feeding system will employ a gravity, screw or belt type feed device.

Working Principles

The FIBC (or big bag) is loaded by hand and unloaded directly by pallet and forklift truck. Various features can be fitted depending on the type of FIBC, also known as bulk bag, used and these include inflatable bag holder, fan driven inflation systems, devices to assist the operator in attaching and automatically releasing the FIBC loops and so on. To this basic unit can be added conveying systems to allow the palletised FIBC to be moved to a convenient position after filling. Weighing is by precision load cells integrated into the frame and a controller allowing different set points to be programmed as required. If required an empty pallet dispenser is supplied. Outputs up to about 30 FIBCs per hour can be achieved with gross weighing.

For higher speeds up to 60 FIBCs per hour, net weighing is the answer with the weighment being dosed at the same time as the FIBC is being attached to the filling spout and loop supports by the operator. Again, the feeding device is properly matched to the product.

Of course, this product range, comprehensive as it is, does not truly demonstrate the innovative Concetti approach to every project and the way systems are adapted to the final user’s precise needs. Examples of this are many and varied but perhaps here we can consider just a few.

Of course, this product range, comprehensive as it is, does not truly demonstrate the innovative Concetti approach to every project and the way systems are adapted to the final user’s precise needs. Examples of this are many and varied but perhaps here we can consider just a few.

Case studies

A customer with a particular material wanted to seal the FIBC automatically for operator safety and transport security so Concetti supplied a strapping system, integrated into the spout so that after filling, the neck of the internal liner was closed tightly with no operator action and sealed to prevent any escape of dust.

In another case, the client wanted to have up to three FIBCs stacked or overlaid on the same pallet to reduce handling operations and Concetti were happy to provide a system that allowed this to be done easily and safely.

Fine powders like cement, present particular difficulties when they are highly aerated during and after filling, potentially giving a highly unstable load. This usually limits the overall output while the powder naturally deaerates until the FIBC can be safely moved. To overcome this problem and to achieve speeds of 25 x 1500Kg FIBCs per hour on cement, Concetti designed a system to provide continuous support for the loops both at the filling point and during transfer to a second deaeration position where additional vibration helps to compact the load, quickly allowing the FIBC to be transported by forklift in complete safety without reducing output.

Concetti’s growing reputation for quality and excellence in bulk materials handling is built on the ability to innovate, to constantly improve quality and reliability and to offer the highest level of world-wide customer service both before and after sale using a hot-line and PLC teleservice by modem.

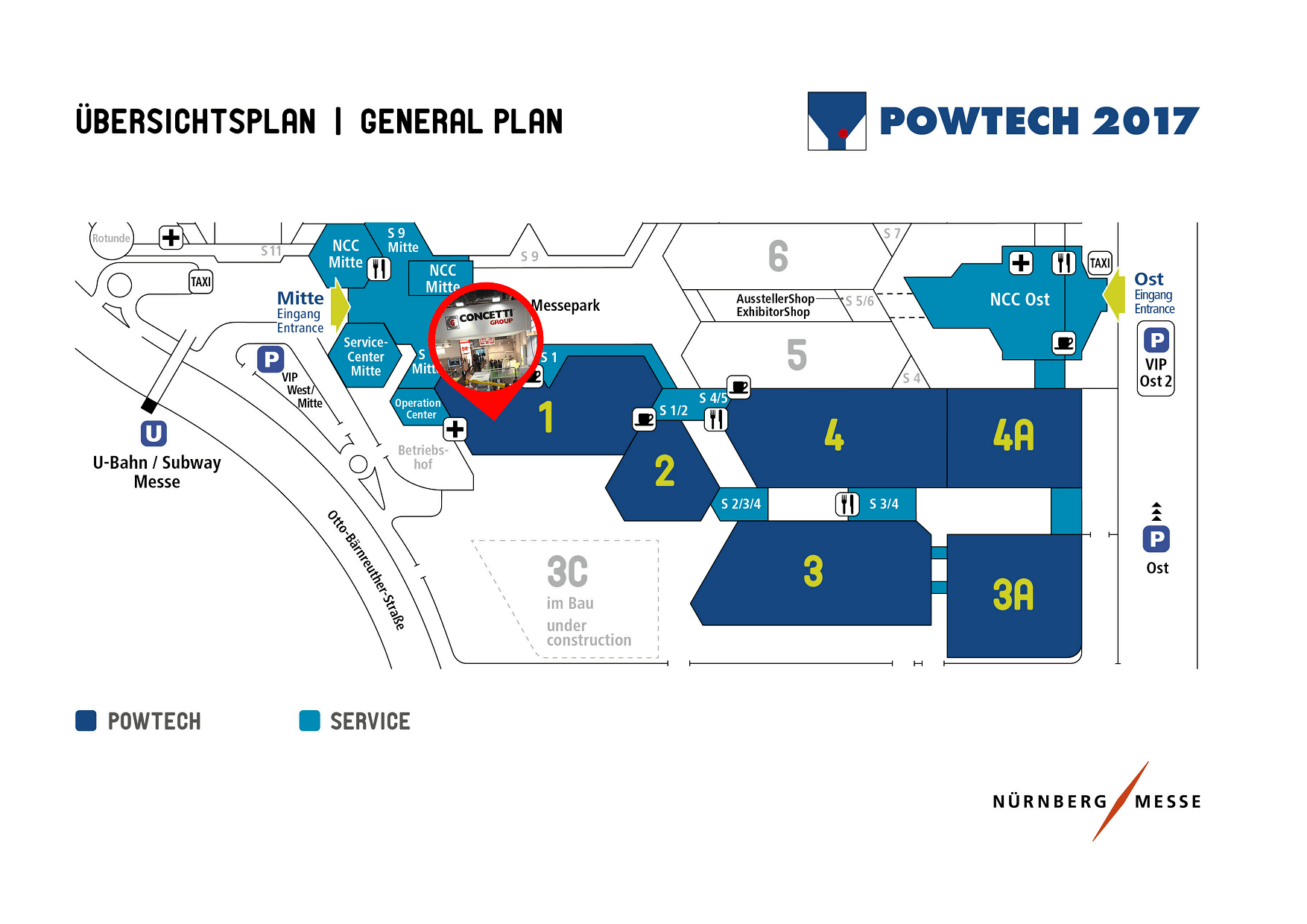

From September 26th to 28th, the latest Concetti equipment and innovations in packaging and filling will be presented at Powtech 2017, the leading trade fair for processing, analysis, and handling of powder and bulk solids, taking place in Nuremberg, Germany.

During Powtech 2017, Concetti will showcase the most innovative bagging solutions for the chemical, pharmaceutical, plastic, food-feed and building industries, designed for tomorrow's smart factory.

Particular attention will be given to the tubular Form, Fill & Seal “Continua”, for handling extra-fine powders. This range of fully automatic equipment for hermetic and recyclable polyethylene sacks, from 10 to 50 kg, with speeds up to 800 bags/hour and the versatility to provide fast changeover between many different packaging formats. The waterproof, clean and squared bags can be palletised easily reducing logistics costs along the entire supply chain.

Concetti experts will be on hand to provide more information about adding value to your business by creating a custom solution for your process.

Be sure to visit us:

Hall 1, booth 1-612

Contact us at

BASTIA UMBRA, ITALY - Improving productivity by monitoring the complete system in a facility will be easier in future, thanks to an innovative software solution that Concetti of Bastia Umbra, Italy - a provider of weighing, bagging and palletising systems - has implemented on one of its most popular machines, the Form, fill & seal for chemical granules.

BASTIA UMBRA, ITALY - Improving productivity by monitoring the complete system in a facility will be easier in future, thanks to an innovative software solution that Concetti of Bastia Umbra, Italy - a provider of weighing, bagging and palletising systems - has implemented on one of its most popular machines, the Form, fill & seal for chemical granules.

This solution, for a smarter “Industry 4.0” factory, offers management the possibility to supervise and review runs of historical data, by checking the production trends and performance of the bagging machine. This powerful solution is helping to reduce plant shutdown times and increase competitiveness by reducing costs.

The system has been developed internally by Concetti engineers, starting with the versatile Ignition application software platform, that unifies all the major software layers in today's manufacturing facilities - SCADA, MES, HMI - into a single solution to record, monitor and analyze the data provided by Concetti equipment, divided by number of bags, production shifts, operators, time intervals, alarm history and so on.

Moreover, the software can acquire data from several Concetti machines, providing a complete view of the production system over time and uses analysis tools to make the process more efficient.

Moreover, the software can acquire data from several Concetti machines, providing a complete view of the production system over time and uses analysis tools to make the process more efficient.

It is a pc panel with a touchscreen interface that combines user-friendliness and the ability to track and display data collected by management in real-time.

The Data Acquisition Software utilizes the industry's most up-to-date technologies and can be fully customized and installed on any type of machine manufactured by Concetti, providing analysis to improve resource management and plant productivity, reduce costs and increase competitiveness.

All machines made by Concetti can also be integrated, interconnected and monitored remotely. For these features, Concetti has received Bureau Veritas's "Industry 4.0 ready" attestation of conformity, for the benefits provided by the 2017 Stability Law, also known in Italy as “Industry 4.0 for packaging machines”.

B.V. -