We put our passion to develop a wide range of high quality automatic bag filling and sealing machines for the international market. We provide complete machinery for filling and closing which are reliable, durable, and technologically superior to standard machines.

As bag filling machine manufacturers, Concetti provides a range of bag filling machines, customized according to the clients’ needs. We also have an always on customer support team throughout the life cycle of the machinery.

Concetti is one of the best bagging machine suppliers in the world thanks to the flexibility and customization of its bag filling and closing machines. In this article we are deeply analyzing the features of all the models of the range.

Concetti worldwide manufactures and supplies weighing and bagging machines for different types of applications and industries. Discover which proposals are most suitable for your company!

Cartesian palletizers stand out for their high reliability, precision, and level of customization. Let’s see all their characteristics and Concetti’s whole range.

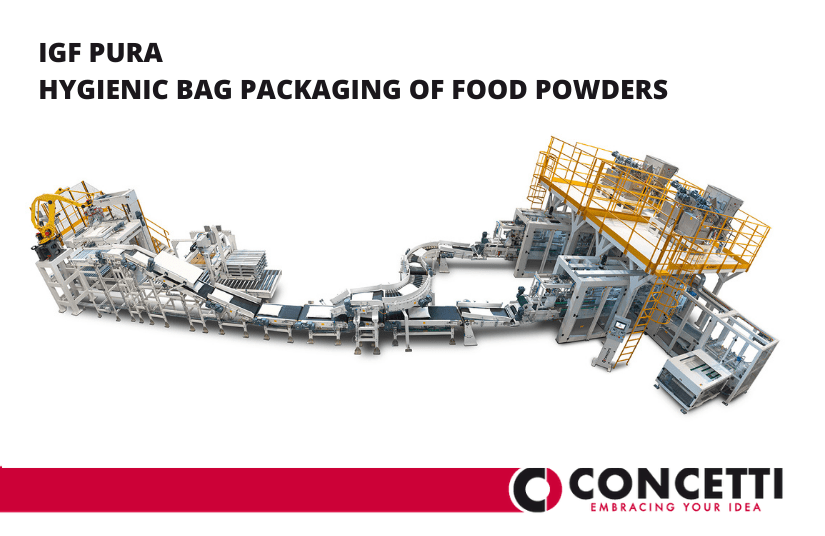

Hygienic, ergonomic and easy to clean, the all-new IGF PURA, an automatic filling and closing machine for powders in 11-110lb bags at speeds up to 13 bpm, was created to ensure the highest product quality in modern food packaging.

To our valued customers, vendors, and service providers -

We are delighted to announce we are moving to a larger, more modern warehouse located at 5450 Technology Parkway, Suite 200, Braselton, Georgia 30517 and will be functioning at that location on May 1st, 2021.

Over 300 delegates registered for the Concetti Webinar held on 25th of February to find out more about Food Hygiene and Ergonomic Design of Bag Packaging Systems.

Since the beginning of the pandemic, Concetti and the two subsidiaries, Concetti North America and Concetti do Brasil, have been actively engaged in efforts to combine the business continuity of its customers with the health and safety protection of its employees and their families.

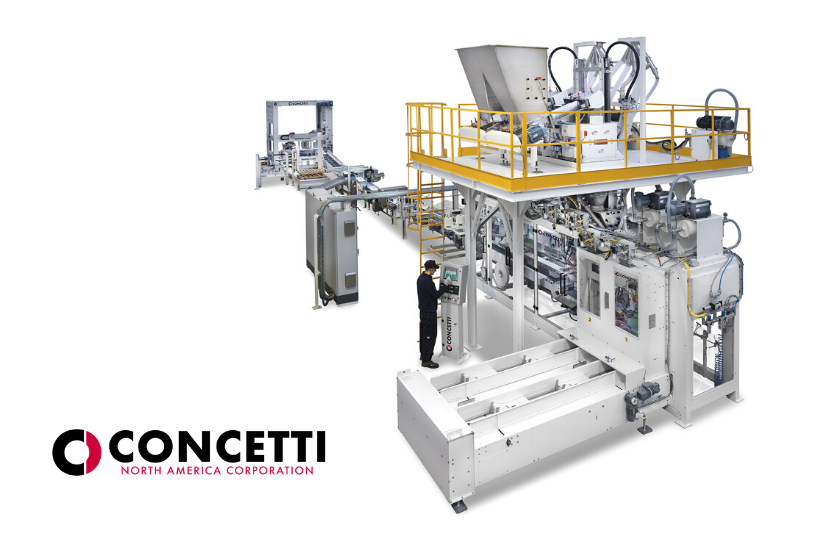

Concetti North America Corp. have installed a complete flour bagging and palletizing system at US Durum Milling, St Louis, MO. The plant, owned by Italgrani USA, is the largest semolina and durum mill in North America.