BASTIA UMBRA, ITALY - Improving productivity by monitoring the complete system in a facility will be easier in future, thanks to an innovative software solution that Concetti of Bastia Umbra, Italy - a provider of weighing, bagging and palletising systems - has implemented on one of its most popular machines, the Form, fill & seal for chemical granules.

BASTIA UMBRA, ITALY - Improving productivity by monitoring the complete system in a facility will be easier in future, thanks to an innovative software solution that Concetti of Bastia Umbra, Italy - a provider of weighing, bagging and palletising systems - has implemented on one of its most popular machines, the Form, fill & seal for chemical granules.

This solution, for a smarter “Industry 4.0” factory, offers management the possibility to supervise and review runs of historical data, by checking the production trends and performance of the bagging machine. This powerful solution is helping to reduce plant shutdown times and increase competitiveness by reducing costs.

The system has been developed internally by Concetti engineers, starting with the versatile Ignition application software platform, that unifies all the major software layers in today's manufacturing facilities - SCADA, MES, HMI - into a single solution to record, monitor and analyze the data provided by Concetti equipment, divided by number of bags, production shifts, operators, time intervals, alarm history and so on.

Moreover, the software can acquire data from several Concetti machines, providing a complete view of the production system over time and uses analysis tools to make the process more efficient.

Moreover, the software can acquire data from several Concetti machines, providing a complete view of the production system over time and uses analysis tools to make the process more efficient.

It is a pc panel with a touchscreen interface that combines user-friendliness and the ability to track and display data collected by management in real-time.

The Data Acquisition Software utilizes the industry's most up-to-date technologies and can be fully customized and installed on any type of machine manufactured by Concetti, providing analysis to improve resource management and plant productivity, reduce costs and increase competitiveness.

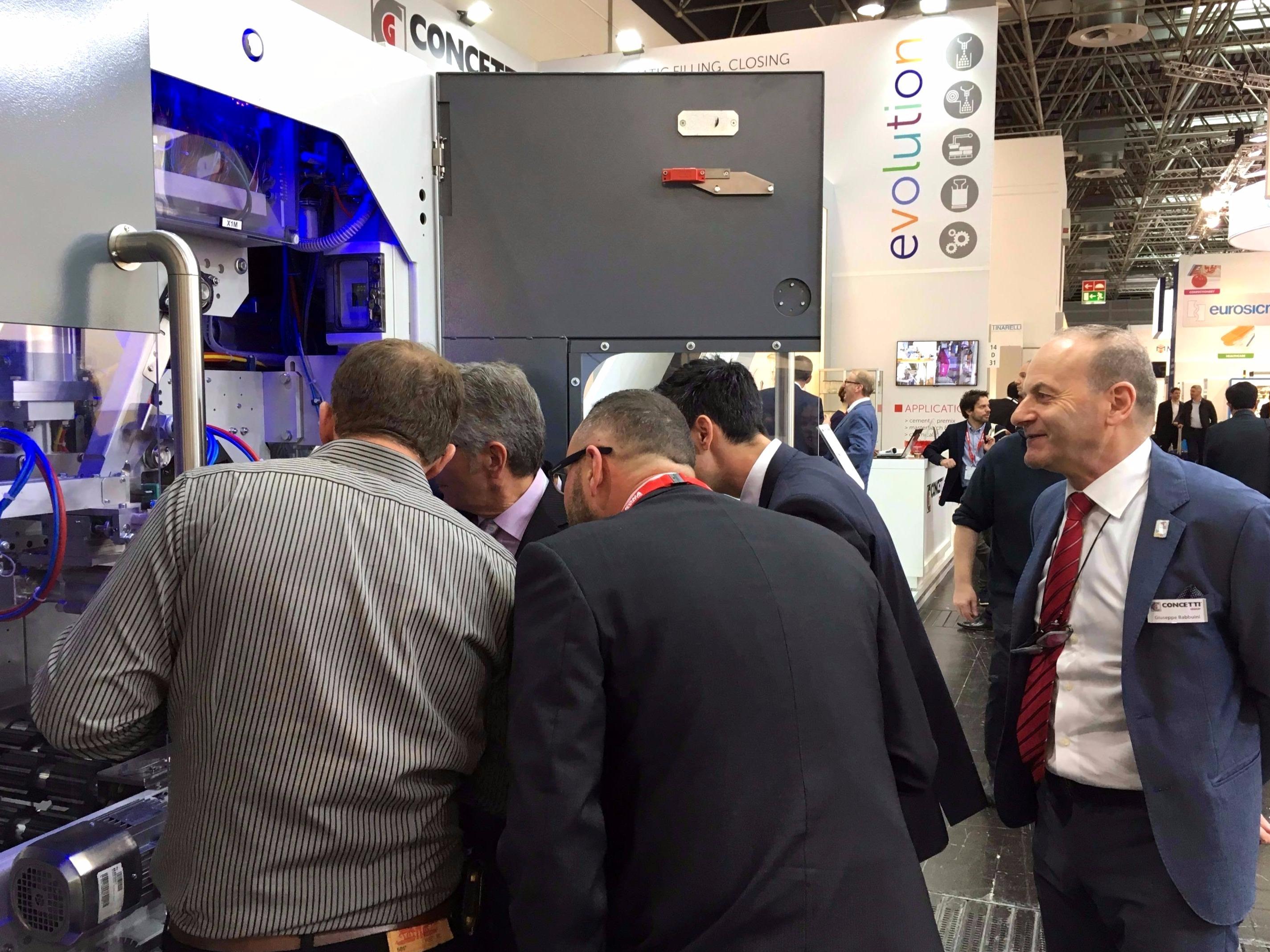

All machines made by Concetti can also be integrated, interconnected and monitored remotely. For these features, Concetti has received Bureau Veritas's "Industry 4.0 ready" attestation of conformity, for the benefits provided by the 2017 Stability Law, also known in Italy as “Industry 4.0 for packaging machines”.

B.V. -

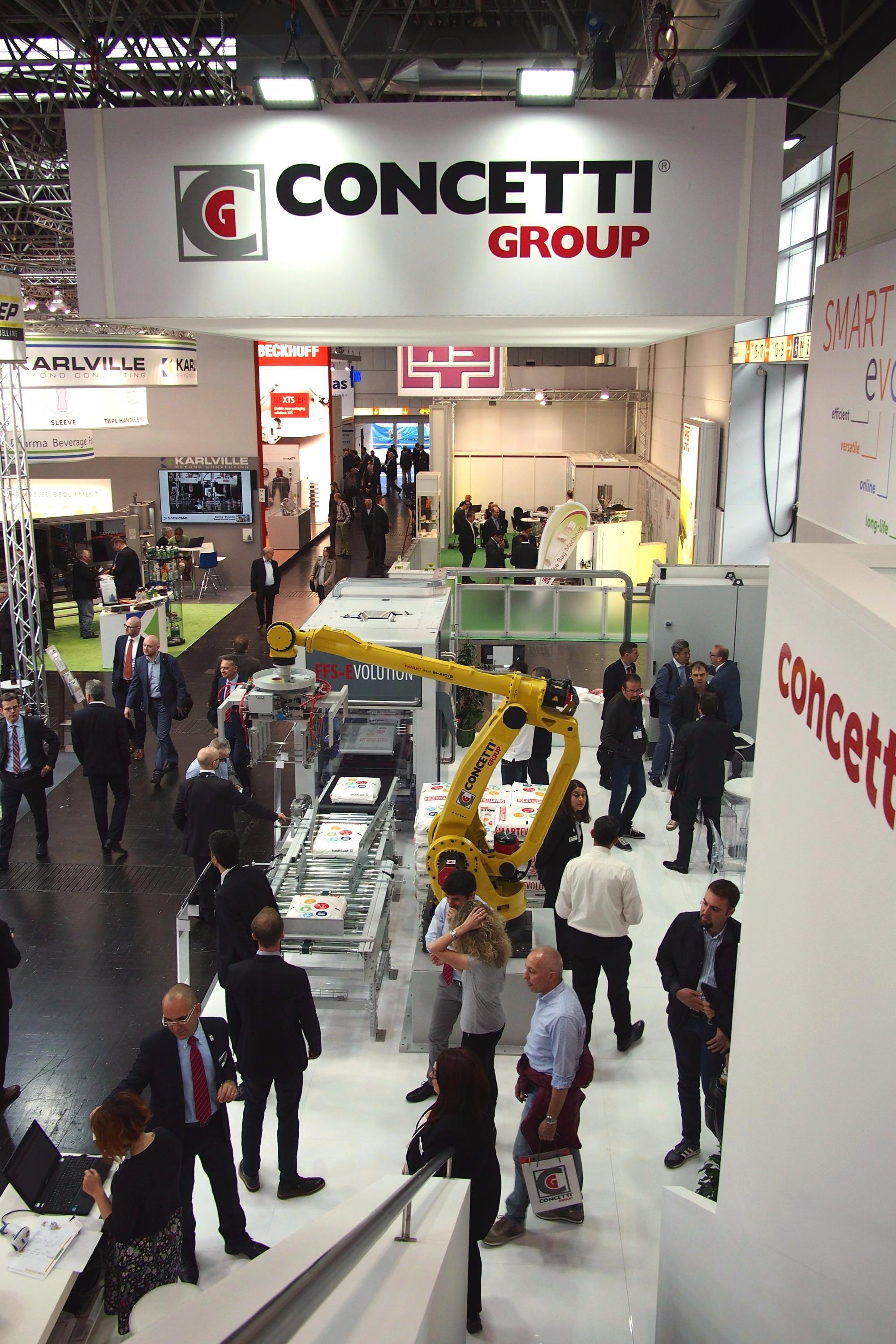

Concetti will take part in Heavy Duty Sacks, the international conference and exihibition on industrial bags and sacks, taking place 27-28 June 2017 at Maritim Hotel, Cologne (Germany).

Concetti will take part in Heavy Duty Sacks, the international conference and exihibition on industrial bags and sacks, taking place 27-28 June 2017 at Maritim Hotel, Cologne (Germany). Concetti will attend the new FVG Select 2017 event, taking place in Cologne, Germany, June 13 and 14.

Concetti will attend the new FVG Select 2017 event, taking place in Cologne, Germany, June 13 and 14.

Concetti has recently supplied a multi-station

Concetti has recently supplied a multi-station January will be the month dedicated to Russian marketplace. Concetti is pleased to announce its participation at “MVC: Cereals – Mixed Feed – Veterinary - 2017” taking place from January the 31st till February the 2nd, 2017, Moscow. The event is considered the largest professional forum in Russia where experts gather to share and exchange new ideas and knowledge.

January will be the month dedicated to Russian marketplace. Concetti is pleased to announce its participation at “MVC: Cereals – Mixed Feed – Veterinary - 2017” taking place from January the 31st till February the 2nd, 2017, Moscow. The event is considered the largest professional forum in Russia where experts gather to share and exchange new ideas and knowledge. The innovative, multi-million dollar packaging system replaces paper bags with a conversion to more robust polyethylene bags. The improved bags offer stronger tensile strength, minimization of nuisance dust and greater control of moisture to maintain the integrity of the material inside. Elimination of trapped air within each bag yields excellent stacking for more stable pallets during shipment, unloading, and warehousing. The new packaging is also easily recyclable which is integral to Huber's commitment to sustainability.

The innovative, multi-million dollar packaging system replaces paper bags with a conversion to more robust polyethylene bags. The improved bags offer stronger tensile strength, minimization of nuisance dust and greater control of moisture to maintain the integrity of the material inside. Elimination of trapped air within each bag yields excellent stacking for more stable pallets during shipment, unloading, and warehousing. The new packaging is also easily recyclable which is integral to Huber's commitment to sustainability.