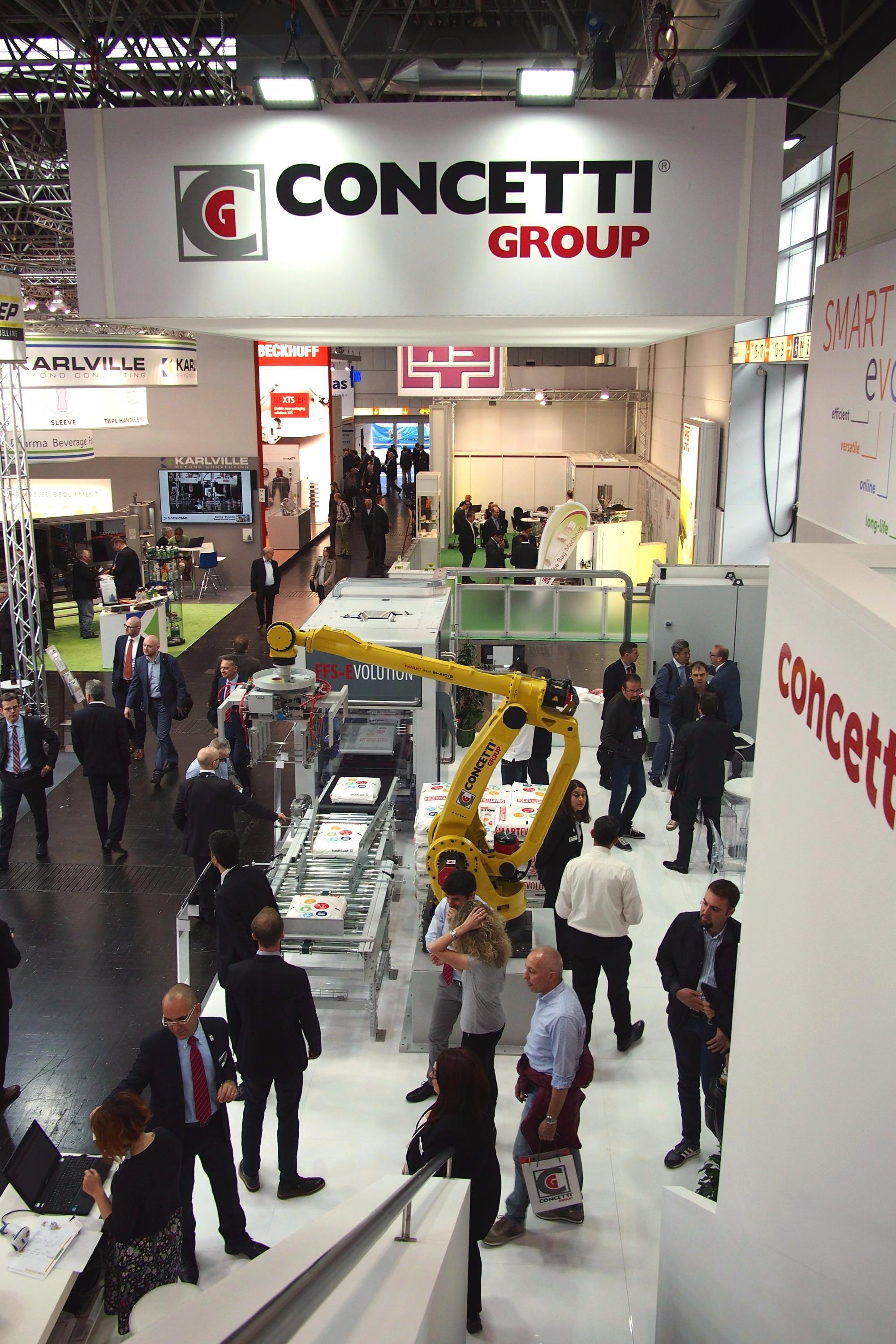

Concetti will attend the new FVG Select 2017 event, taking place in Cologne, Germany, June 13 and 14.

Concetti will attend the new FVG Select 2017 event, taking place in Cologne, Germany, June 13 and 14.

The Italian manufacturer of high quality packaging machinery has been providing complete bagging lines for over 40 years, offering the flexibility to handle a wide range of packs and closures, and the ability to switch rapidly from one product and pack size to another in less than 90 seconds.

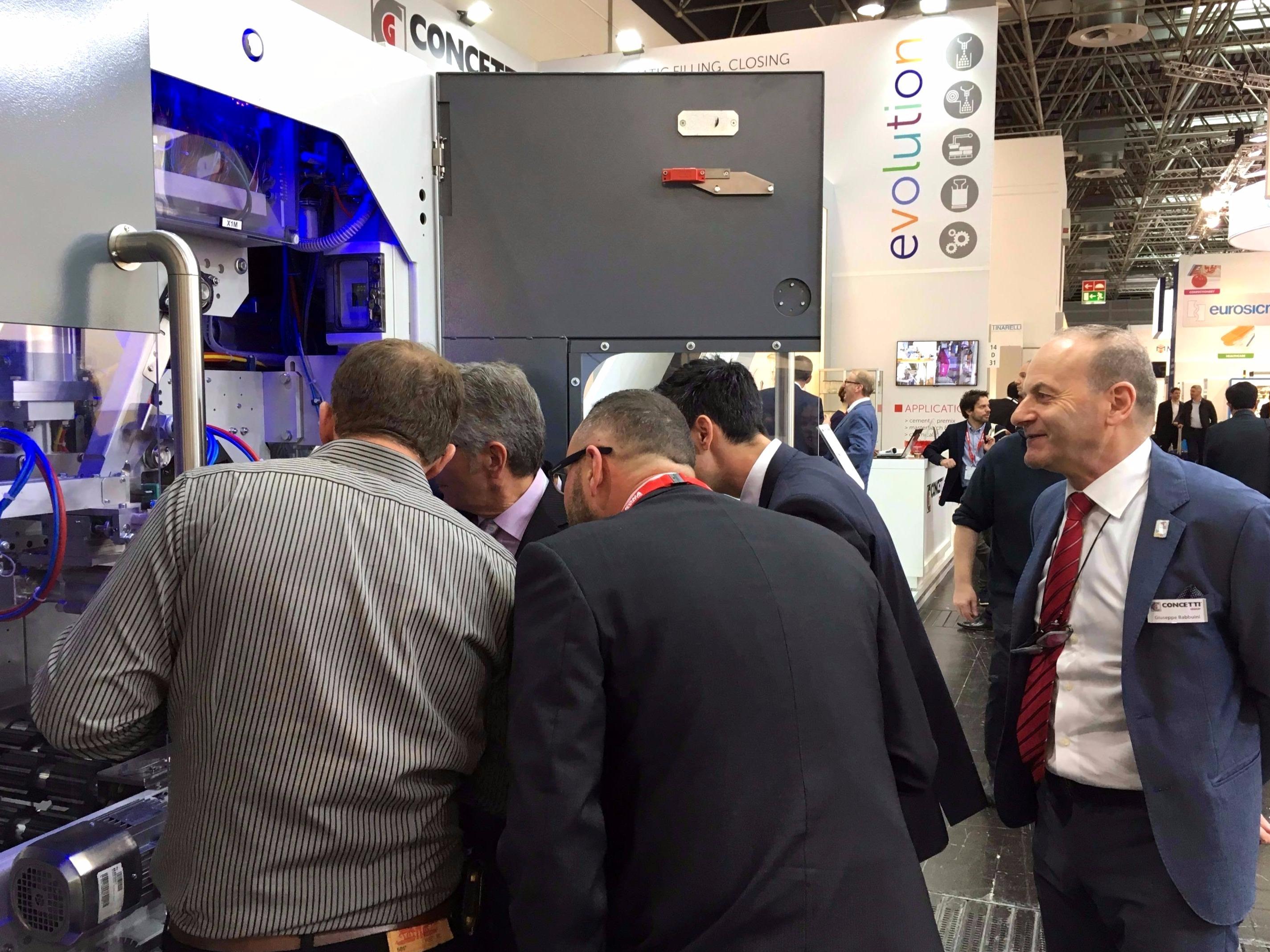

The fully automatic IGF bagging system, for example, is designed for any kind of open mouth bags from 2 to 50 kg: flat or gusseted, paper, coated paper, PE, aluminium, woven PP bags with or without handless, quad sealed laminated bags with pre-applied zipper. Concetti can now offer Modified Atmosphere Packaging (MAP) as an option on its fully automatic bagging systems. This is designed to help animal feed producers offer the very best quality of product and improve profitability.

Will you attend FVG Select 2017? Schedule an appointment:

Concetti has recently supplied a multi-station

Concetti has recently supplied a multi-station January will be the month dedicated to Russian marketplace. Concetti is pleased to announce its participation at “MVC: Cereals – Mixed Feed – Veterinary - 2017” taking place from January the 31st till February the 2nd, 2017, Moscow. The event is considered the largest professional forum in Russia where experts gather to share and exchange new ideas and knowledge.

January will be the month dedicated to Russian marketplace. Concetti is pleased to announce its participation at “MVC: Cereals – Mixed Feed – Veterinary - 2017” taking place from January the 31st till February the 2nd, 2017, Moscow. The event is considered the largest professional forum in Russia where experts gather to share and exchange new ideas and knowledge. The innovative, multi-million dollar packaging system replaces paper bags with a conversion to more robust polyethylene bags. The improved bags offer stronger tensile strength, minimization of nuisance dust and greater control of moisture to maintain the integrity of the material inside. Elimination of trapped air within each bag yields excellent stacking for more stable pallets during shipment, unloading, and warehousing. The new packaging is also easily recyclable which is integral to Huber's commitment to sustainability.

The innovative, multi-million dollar packaging system replaces paper bags with a conversion to more robust polyethylene bags. The improved bags offer stronger tensile strength, minimization of nuisance dust and greater control of moisture to maintain the integrity of the material inside. Elimination of trapped air within each bag yields excellent stacking for more stable pallets during shipment, unloading, and warehousing. The new packaging is also easily recyclable which is integral to Huber's commitment to sustainability.

The European dry pet food market is a sophisticated and highly competitive one, with a wide and constantly expanding range of packaging formats, especially at plants supplying own-label products to other brand owners. Unless a manufacturer invests in several different and expensive packaging systems, a single line must be capable, not only of managing the widest possible range but also be future proofed with the ability to adapt to new bag weights, types and sizes according to changing market demands.

The European dry pet food market is a sophisticated and highly competitive one, with a wide and constantly expanding range of packaging formats, especially at plants supplying own-label products to other brand owners. Unless a manufacturer invests in several different and expensive packaging systems, a single line must be capable, not only of managing the widest possible range but also be future proofed with the ability to adapt to new bag weights, types and sizes according to changing market demands.