Capital Refractories, a British manufacturer of innovative, heat resistant castable refractories recently installed a complete Concetti filling and palletising line at their main manufacturing site near Chesterfield, UK.

The fully automatic system handles a wide range of dense, highly abrasive cement-like materials for furnace lining applications and is part of a planned switch by Capital Refractories to greener, more environmentally friendly packaging materials. The use of unperforated PE film creating a hermetically sealed finished pack, prevents moisture ingress and reduces product wastage.

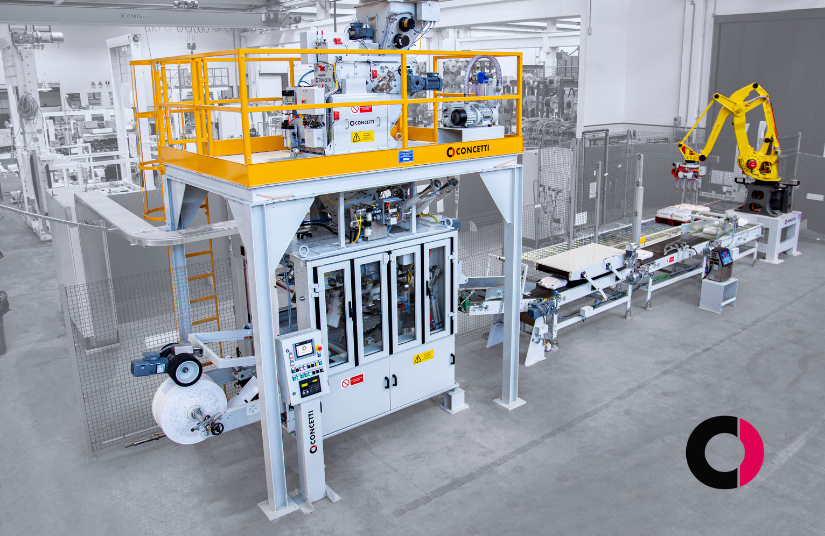

Customised by Concetti’s in-house design team, the line has an output up to 440 x 25Kg bags per hour. Key to providing a long service life is the use of replaceable liner plates manufactured from special wear resistant steel to combat abrasion on all high impact surfaces.

From the MNET/N net weigher, through the Continua 600 form fill seal machine to the PS-4A/15S-A-Fanuc robot palletiser, Concetti provided the complete line from its own extensive product range and using the experience gathered from 45 years of designing and supplying bag filling systems.

The compact, highly integrated line is controlled from a single position, allowing the operator to change product types via a keyboard without manual adjustments, a well-known feature of all Concetti systems.