Hygienic, ergonomic and easy to clean, the all-new IGF PURA, an automatic filling and closing machine for powders in 5-50 kg bags at speeds up to 750 per hour, was created to ensure the highest product quality in modern food packaging.

Concetti redesigned the proven IGF, following the latest international machinery hygiene guidelines. From avoiding product retention, using specific contact-part materials and providing convenient access for cleaning, everything is geared towards safeguarding the final product.

The dual-auger fed integrated scale is:

1. Completely accessible using quick release panels;

2. Automatic in-place cleaning is achieved by air-blast nozzles in the auger casing, combined with reversable screw direction to clear residue into a floor level container;

3. Augers are removable for more thorough cleaning;

The monobloc structure has transparent panels, electrical and pneumatic connections sealed in the machine frame and generous internal space to aid cleaning and maintenance operations. A touchscreen panel with easy-to-use graphic interface permits easy control and supervision while the redesigned bag magazine is more operator-friendly: both for loading and accessing coding, printing, and labelling devices.

Closing options showcase Concetti’s reputation for flexibility. From simple sewing to combined folding, stitching and welding of internal PE liners with ‘easy open’ feature, all guarantee security of the closure.

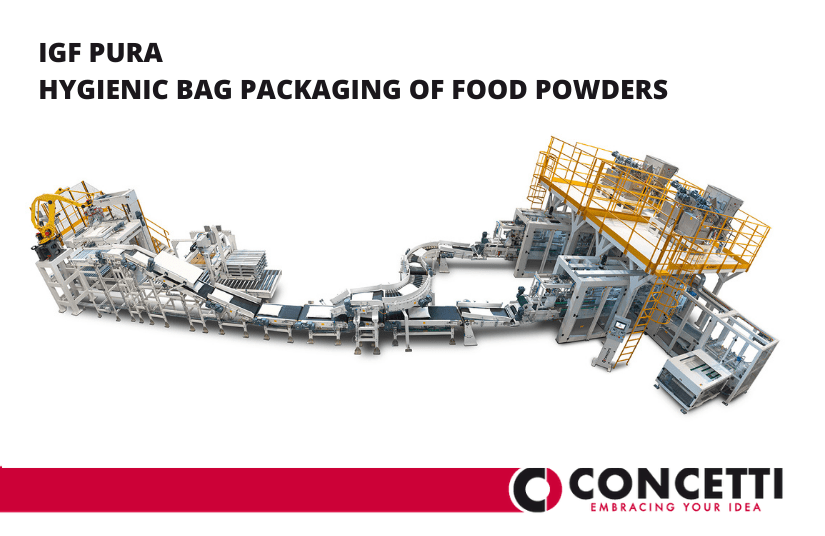

Concetti, as a manufacturer of complete packaging and palletizing lines, ATEX certified for potentially explosive atmospheres if necessary, provides a single, reliable source for all your bag filling needs.

Palletisers includes single arm robots to conventional layer machines all designed to provide stable pallets for safe handling. Pallet wrapping machines give added protection and security.

> Register to watch the webinar Hygienic & Ergonomic Design of Bag Packaging Systems