With one-of-a-kind machines, Concetti stands out in the market by offering bag palletizing systems with different performance levels to meet a wide range of production needs.

Concetti's automatic bag palletizing machines are extreme flexible and compact systems. They provide stable, safe pallets with defined geometry, no matter what type of bag is being processed. Concetti has a wide range of palletizers with different performances depending on the type of bag and its contents: push, robotic, anthropomorphic, and for bags in box.

Due to its many years of international experience and certifications, Concetti can offer all the bag palletizing solutions on the market for all kinds of needs and speeds.

In this article we will look at the features of some Concetti machines and the advantages of relying on us:

Bag palletizing systems by Concetti

Concetti's range of bag palletizing systems includes several product categories, each indicated for a type of bag, depending on the bag material and the product contained (granular, powdered, etc.). Let’s discover more about them and how they work.

High-level bag palletizing machine

Automatic high-level bag palletizing machines are particularly suitable for high-speeds with stable bags with well-defined geometry. SInce several operations are performed simultaneously, high production capacities can be achieved with these automatic palletizers.

Low-level bag palletizing system

Low-level bag palletizing systems are particularly suitable machines for achieving medium speeds with stable bags. Connecting the palletizers to filling lines, even existing ones, is easy. Size changeover takes place in a short time and without operator intervention, thanks to the actuators on the machine and theelectronic control.

Single-column bag palletizer

Single-column bag palletizing systems are made by small dimensions and ease. They can process stable, aerated, and inconsistent products, and allow partial overlapping of bags in the layer, both head, and side. It is flexible in size changeover, while its extreme simplicity also allows palletizing on pallets directly laid on the ground.

Robot bag palletizer

Roboting arm bag palletizing system is the most versatile and flexible machine in the range. Thanks to its movable arm, it can process bags containing stable, aerated, inconsistent products and it is flexible in format changeover. It also allows palletizing of pallets directly resting on the ground.

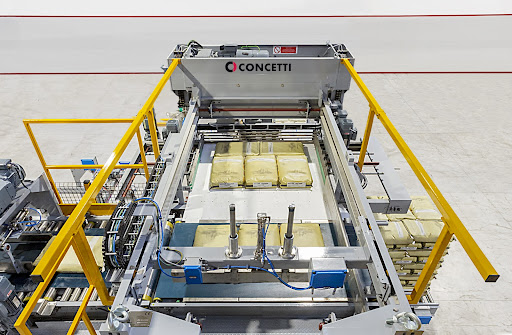

Gantry type bag palletizing machine

Gantry type bag palletizing machines can be installed in relatively small spaces due to their small dimensions. They are suitable for palletizing both stable bags and difficult bags since they are half empty, or contain products at the viscosity limit or aerated. Its strength is the relatively short pallet formation times and the maintenance of a very high precision and repeatability of movements.

If you need a bag palletizing machine, request a free quote.

Four-column bag palletizing system

For-column bag palletizer is a robust and versatile machine that allows palletizing even with bags that are not completely full. It allows good stability and geometry to the palletized load, regardless of the shape and type of the bags (valve, open-mouth, paper, raffia, PE, etc.), their degree of filling, or the nature of the material they contain.

Automatic palletizer for bags Lampo

Lampo is a palletizing system that combines the reliability of a conventional palletizer with the flexibility of industrial robots. It ensures well-stacked, compact, and solid bag pallets and it is particularly suitable for unstable products and partially filled bags.

Bag in box palletizer

Bag in box palletizer is suitable for special applications such as the palletizing of pet food in different formats. In this context, flexibility is a key requirement, and for this type of product the demand is mainly for small format packages, so production speed is a key factor. This is a PS-4A/15S-P gantry-type robotic palletizer for canned bags with a production capacity of up to 1400 bags/hour.

Quality assurance by Concetti

Every customer of Concetti can enjoy a number of guarantees and benefits that will assure them of the quality and performance of the bag palletizing machines among others.

First of all, each customer has the opportunity to visit the company's Italian headquarters to test and verify firsthand the operation of the bag palletizing systems. Only then, once the F.A.T. has been performed, the machines are shipped to the customer's site, assembled, and started up. The F.A.T. is a pre-installation to ensure that the contract specifications are fully met. At this stage, the plant is assembled in its entirety in our Italian factory and put into operation with the customer's bags and materials, thus speeding up subsequent installation and testing at the customer's factory.

Concetti remains at its customers' side throughout the bag palletizing machinery lifecycle, thanks to the new Check services, Customer Help Care Kit for field and remote assistance. Alongside a range of digital services (customer portal, Check app, smart glass assistance, etc.), our customers can rely on direct support from local service centers (Campinas, SP, Brazil and Braselton, GA - US) with teams of experienced technicians who can travel directly to the site upon request. In addition, there is an appreciated training service for customer personnel to properly operate the machines.

Do you need a bag palletizing system for your production line?