Concetti provides a wide range of automatic palletizers for every industry. Let's find out more about their features and operation.

An automatic palletizer is a robotic device used to stack and organize products on a pallet. We design and supply automatic palletizers for different industries with specific requirements and characteristics.

In this article, we will explore the following topics:

- What is automatic palletizing

- Concetti’s range of automatic palletizers

- How does an automatic palletizer work?

- All the advantages of automatic palletizing

What is automatic palletizing?

Palletization is a procedure for stacking bags containing different types of products on pallets. When we talk about an automatic palletizing system, it means that advanced automatic machines enable the precise movement and transportation of goods to the destination area with minimal human intervention.

Concetti specializes in the production and commercialization of custom-made automatic palletizing systems that meet the diverse needs of all industries. Our automatic palletizers are equipped with state-of-the-art robotics, precision sensors, and high-speed conveyor systems to ensure maximum efficiency and reliability.

Since 1975, we have been producing cutting-edge automatic palletizing solutions for every type of packaging and different types of products, from pet food to cereals, granules, or loose powders. Our systems feature intuitive control interfaces, real-time monitoring, and adaptive algorithms that optimize stacking patterns, significantly reducing downtime and enhancing throughput.

Concetti's automatic palletizers

Concetti boasts a wide range of automatic palletizing systems tailored to meet the specific needs of various industries. These products are customized and built in close collaboration with clients, showcasing the diversity in their functionalities and applications.

High-level automatic palletizers

High-level automatic palletizers from Concetti feature a rigid structure with a vertically sliding frame that holds the pallet during production. Ideal for stable bags with a well-defined shape and high-speed movement, these palletizers allow for simultaneous operations, achieving high production capacities.

Low-level automatic palletizers

Characterized by a rigid structure that moves vertically with a trapdoor mechanism for unloading bags onto pallets, low-level automatic palletizing systems are suited for stable bags at medium speeds. They can be easily integrated with existing or new filling lines.

Robotic arm palletizers

The robotic arm automatic palletizing system can handle a range of bagged products, including stable, aerated, and loose contents, allowing for partial overlapping of bags. This machine is extremely easy to use and allows you to palletize even on pallets sitting directly on the floor.

Gantry type automatic palletizers

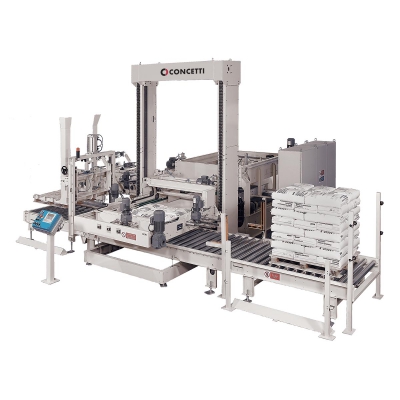

Gantry style palletizing systems are compact, space-saving units that can be installed even in limited spaces. They feature a robust, compact structure with a specially designed robotic arm, capable of integrating various gripping devices and handling all types of bags, cardboard, and bundles.

Four-column palletizers

The four-column robotic automatic palletizing system is designed for handling not fully filled bags or those containing aerated or powdered materials, providing exceptional flexibility. It operates with a gripper moving along three Cartesian axes and rotating around its vertical axis.

Single-column palletizers

The simplest and most compact model in Concetti’s range, the single-column automatic palletizing system processes stable, aerated, and loose products. It allows partial overlapping of bags both on top and sides and offers flexible format changes. Its simplicity facilitates palletizing even directly on the floor.

Bag in box palletizer

The robotic bag-in-box automatic palletizing system achieves a production capacity of up to 2700 bags/hour. It is equipped with heads featuring suction cups and vertical movement to pack bags and boxes into pre-formed corrugated cardboard boxes (pallet display units), enhancing product protection during transport and storage.

Lampo Palletizer

The LAMPO is an advanced automatic palletizing system for bags, bundles, and boxes, blending the reliability of conventional palletizers with the flexibility of industrial robots. It creates compact and solid pallet stacks through the configuration of individual layers, combined with vertical side compaction and a highly flexible shell-type gripping head.

Do you need an automatic palletizer?

How an automatic palletizer works

Automatic palletizers operate in two main ways. Some machines, equipped with mechanical arms, transfer goods from the bagging line to the palletizing point. The goods, once bagged, are transported on a conveyor belt and positioned by the mechanical arm according to pre-defined palletizing patterns. This type of palletizer is highly versatile and can be used in industries ranging from food to chemicals, where precision and flexibility are crucial for handling diverse product types and packaging.

Other systems, such as low-level and high-level palletizers, use a "push" method where the filled bag is pushed onto a layer-forming plate before being palletized. Low-level palletizers are ideal for medium-speed operations and are commonly used in industries such as agriculture and animal feed, where they handle products like grains, seeds, and pet food. High-level palletizers, on the other hand, are suited for high-speed operations, making them perfect for industries with high throughput demands, such as the chemical and cement industries.

The entire process is efficiently managed via a PLC (Programmable Logic Controller), which offers an intuitive user interface. This allows for seamless integration with existing production lines and easy adjustments to palletizing patterns and operational parameters. In industrial applications, this capability ensures that palletizing systems can be tailored to specific production requirements, enhancing productivity and reducing downtime. The PLC also supports real-time monitoring and diagnostics, enabling preventive maintenance and minimizing the risk of operational disruptions.

Advantages in automatic palletizing

Automated palletizing and palletizers have several advantages over manual palletizers:

- Ease of operation: automated systems are designed with user-friendly interfaces, making them simple and intuitive to operate.

- Enhanced safety: they offer greater safety for operators by reducing the risk of workplace injuries associated with manual handling.

- Increased production efficiency: automated palletizers can handle high-speed operations, significantly increasing production rates and reducing downtime.

- Improved pallet compactness and load distribution: they provide superior results in terms of pallet compactness and load distribution. Efficient logistics save money by ensuring well-squared pallets without protrusions, which prevents packaging breakage and product loss. This is especially crucial for high-quality, technical products, where loss or damage can result in significant economic losses for the end customer.

- Secure packaging for transportation: automated systems ensure secure and well-executed packaging for transportation, preventing product leakage into the environment.

- Consistency and precision: automated palletizers ensure consistent stacking patterns and precision, which is difficult to achieve manually, leading to uniform and reliable pallet loads.

- Adaptability: they can be easily reprogrammed to handle different products and packaging types, offering flexibility to adapt to changing production needs.

Do you need more information about automatic palletizing?