Concetti has the right dog food filling machine for you, whether you’re dealing with kibble, dry pet food croquettes in different sizes and with various recipes.

Thanks to our extended experience in the pet food sector, we are able to manufacture innovative dog food filling machines that offer flexibility and increased outputs.

On this page, we will delve into:

- The Concetti range of dog food filling and bagging machines

- How the filling operation works in dog food filling machines

- The latest technology for our solutions

The Concetti range of dog food filling and bagging machines

Concetti has proposed a new way of conceiving packaging machinery, especially for the pet food industry. Our machines are the unique combination of safety, perfect cleaning mechanisms, and solid structure without compromises.

Discover our high-performing dog food filling and bagging machines.

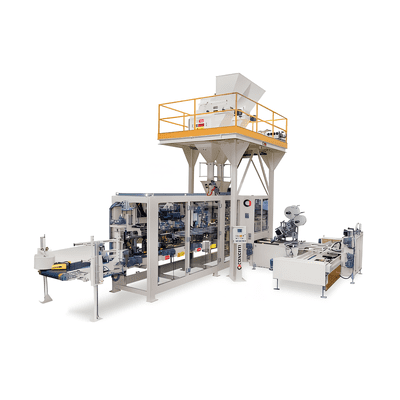

IMF dog food filling and bagging machine for pre-formed bags

The IMF model needs to be mentioned in the vast landscape of our pet food filling and bagging machinery. It has been designed and engineered specifically for dog food, automatically accommodating pre-formed bags with the utmost precision, occupying very little space.

A feature worth noticing is its dual discharge spouts and a pair of empty bag magazines, ensuring an excellent output rate of 1,400 bags/hour.

The characteristic that distinguishes IMF from other dog food filling machines is its incredible ability to effortlessly adapt to different

- bag formats - from a 4.4 lbs to 44 lbs;

- materials - from paper and coated paper to PE, PET, PE-alu-PE;

- bag type - gusseted or flat (pillow).

Among the multiple bag-closing systems it can handle, IMF can manage:

- Simple sewn closing: this is a method of sealing where the open side of the bag is stitched by using a thread.

- Sewn closing with crepe tape: in this case, the bag is sewn by adding a layer of crepe tape beneath the sewing part, further protecting the product from contaminants.

- Sewn closing with adhesive tape: in this case, which is similar to the sewn closing with crepe tape, the bag is sealed by using a strip of adhesive tape, placed over the bag’s opening.

- Hot-melt closing: hot adhesive is applied to the opening of the bag, and then pressed. Once cooled, the adhesive becomes solid, closing the bag.

- Heat-sealing: this method involves the bag’s open side to be directly fused, creating a seal. This can be effective if the bag is made of thermoplastic materials.

- Pinch-top closing: in this case, the top part of the bag is pinched, or pressed.

For extra safety, our machinery is compliant with the current EC regulations, and is PLC controlled in order to set precise parameters, ensuring excellence at every production cycle.

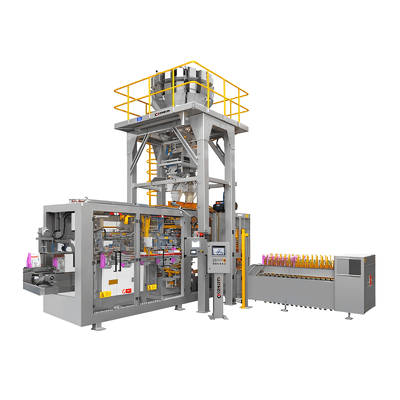

IPF machine fills bags from 0.22 to 11 lbs and reaches a production of 1,800 bags per hour

Concetti’s IPF dog food filling and bagging machine is fully automated and highly customizable both for open-mouth pillow and gusseted bags.

It can fit any production environment thanks to its optimal dimensions and, as the IMF model, it’s versatile, effectively handling bags from 0.22 lbs to 11lbs thanks to a series of self-adjusting components which accurately proceed with the filling and sealing operations.

From simple sewing to heat-sealing and pinch-top closing, IPF can execute impeccable seals that preserve the properties of pet food.

Due to its automated nature, it’s possible to set up the parameters through the PLC system.

Passing from a bag format to another is a fully automatedprocess and it’s carried out in 60 seconds without any manual intervention on the operator’s behalf.

Within the IPF dog food filling machines, you can find the IPF 40 which can reach up to 2,000 bags/hour thanks to its dual bagging mouths.

Would you like to know more about our dog food filling machines?

How the filling operation works in dog food filling machines

Our dog food filling and bagging machines are made out of accuracy and dedication. The goal was to create a versatile piece of machinery that could manage even the most complicated tasks.

Their components are highly sensitive to bag shapes, properly restoring gussets across various formats and dimensions. Furthermore, we have a patented system that can handle even the quad seals and vertical seals seamlessly, enhancing the whole closure operations.

How does the filling procedure take place, though?

Concetti’s innovative filling methods include making the bag’s bottom vibrate for a compact distribution of dog food, aiming at making the palletization process easier, and minimizing bag length.

Once the bag is closed, the air in excess is expelled with a specialized roller mechanism.

The IPF, IGF, and IMF models have the opportunity to perfectly heat-seal PE bags, even adding dual seals for added security. Concetti also employs an internal sealing mechanism to seal the bar with a Teflon sheet reel.

In the current market context, machines need to be more and more fast, ensuring incredible outputs in terms of filling and bagging at all times and with all bag formats, reducing the operator’s strain.

The latest technology for our solutions

Discover the latest technology we have implemented in our dog food filling machines in order to reduce product waste and optimize each operation.

- Hermetic Quad seal or Stabilo closure to avoid dog food contamination and preserve its properties and its quality.

- Optimal welding of PE, PET and Alu-PE bellows bags thanks to a welding system built using solid and high-quality components

- Cooler system

- Vibration device to compact the product to facilitate the palletization.

- Deaeration device

- Mechanism to close the bags at different heights

Would you like to know more about our dog food filling machines?