The Concetti Group complete packaging lines for ceramic frits, dyes and glazes are a perfect example of quality and flexibility that has led internationally renowned groups like Ferro and Colorobbia to repeatedly give us their preference over the years.

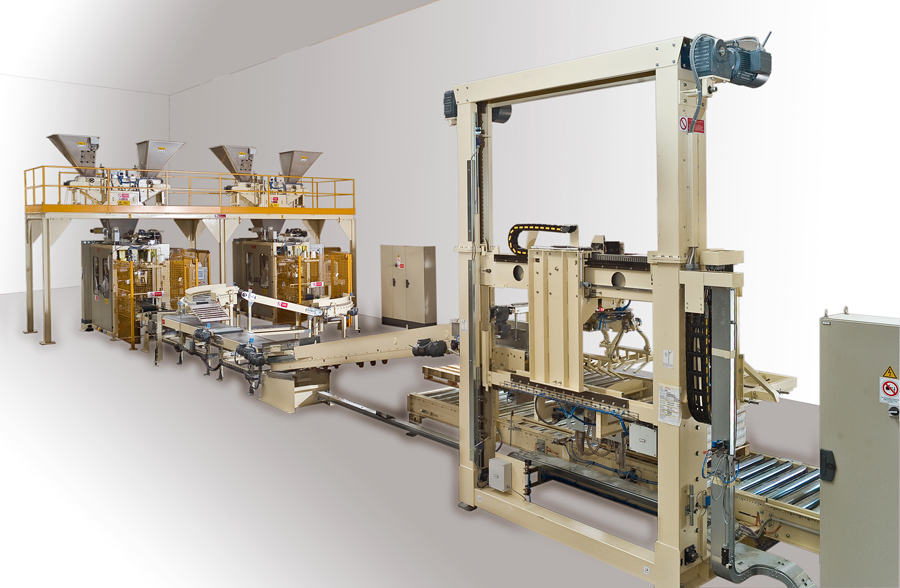

Given the fine and powdery form of this product family, the Clients usually need to be able to clean the feeding system very accurately, especially if they need to switch from one product to the next in a limited amount of time: to satisfy this request, Concetti Group has featured a special easily dismountable screw-fed feeding system to convey the products to the gross or net weigher.

This double screw system (one for the gross weighing and the other for the fine weighing) is supplied with easy-open inspection doors complete with micro-switch and a dedicated catwalk with access ladder to guarantee a fast and comfortable cleaning, that may also be carried out by extracting the screws and replacing them in their cradle in no time.

In addition to all these interventions, to maintain a clean and safe work environment, the Concetti Group turnkey packaging system for frits, dyes and glazes is equipped with a deaeration devicewith probes to eliminate most of the air from inside the bags and a dust suction device, fitted on the GROSS/CC or NET/CC weigher, that can be connected to the general aspiration system of the Client’s working site. To avoid any corrosion or consumption, the parts in contact with the product are supplied in stainless steel.

Once the weighing cycle is complete, the product is conveyed to the IGF bagging machine, used to work pre-made bags made of paper with PE in-liner. Alternatively, Concetti may offer its Form-Fill-Seal machine CONTINUA, which fills bags obtained by a PE tubular reel and is fit and very well-performing with these products. Both IGF and CONTINUA come equipped with a vibration and an air-elimination device.

After being either stitched (IGF) or heatsealed (CONTINUA), the bags are conveyed to a 2- or 4-column robotic palletiser (PS-4A/15S).

Reaching a speed ranging from 150 to 450bags per hour – according to the products peculiarities – these Concetti Group solutions are another outstanding example of our versatility, always aimed to long-lasting quality.